Reduced coke prices have led to an upsurge in the demand for low grade iron ore fines. Reports show this trend has been witnessed mostly for super special fines and Fortes-cue blended iron ore fines. These Indian fines have witnessed a surge in both seaborne and port-side markets since February this year.

Indian origin iron ore fines are in great demand across the world. The demand for Indian iron ores is more as it is high in alumina and low in phosphorous content and it is best to be blended with either domestic concentrates or Iron Ore Carriages (ICJ) fines for cost-efficiency.

News reports suggest many Chinese companies are buying more Indian fines these days and plan to blend it with IOCJ.

By using iron fines companies have realised that they can utilize a lot of the resources that were otherwise just being wasted.

On the other hand, to meet the demand, iron ore producers had to increase resource base, increasing production and productivity, utilize low grade iron ores, fines and slimes.

It is under this purview that businesses in the iron and steel industry came up with the idea of utilizing iron fines and coal fines generated during mining and transportation which were earlier considered as waste. Left in the open on mine sites, iron fines are a source of pollution and a hazard to the environment.

So what exactly are iron ore fines?

Iron ore fines are derived from the natural raw iron ore. Thee resource is extracted through the process of mining, crushing and screening. The separated iron ore lumps and fines are used in the iron-steel making industry. If the iron ore content in the processed iron ore contain more than 60% iron, it is called as lumps and they are shipped directly to the plants.

The less desirable iron ore fines are first sintered before they can be utilized for blast furnaces. Industry standards state that the size of iron lumps lie in the range of 6.3mm to 31.55mm whereas iron fines are less than 6.33mm.

In India major haematite type deposits are found in Orissa, Jharkhand, Chattisgarh, Maharashtra, Goa and Karnataka. According to studies the country has major resource potential of extracting low grade iron ore in these belts too.

Voltcon's iron ore fines

Mineral resources play a great role in the industrial development of a country. Even though India has a rich resource of high-grade iron ore it is important that it uses its resources judiciously and keeps in mind the conservation of environment.

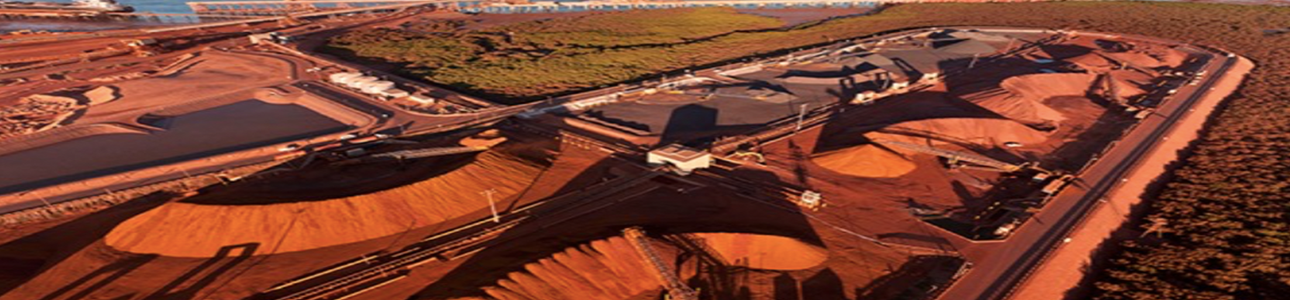

Voltcon is a leader exporter of iron ore and fines in Indian and at present Voltcon exports Iron Ore Fines from Paradip, Haldia and Vishakapatnam ports. The company at present gets iron ore fines from different iron producing Indian states such as Odisha, West Bengal, Jharkhand, Andhra Pradesh & Chhatisgarh.

How Voltcon iron ore stands out?

Voltcon products have iron content. The low undersize lump ore breaks down less during handling and transportation so customers receive a larger fraction of valuable lump ore. Voltcon iron fines create less dust during handling and transportation so there is less ore loss and have less impact on the environment.

Besides this Voltcon iron ore has an excellent thermal shock resistance. This is very important as lesser fines are formed in the top of the blast furnace.

The benefit of this is that fewer fine particles of the fines are lost to the off-gas and the burden they become more permeable. Another highlight is that the lower fines formation in the blast furnace increases the permeability of the burden this reducing the need for coke usage.